Restoration

This version of the Grand Prix began its life as a kit of parts. The whole lot was packed into a rented SUV for its journey from New York State, across the Canadian border, and into Ontario. Only when we spread the entire caboodle out on a camping groundsheet could we view the true generosity of its previous owner. Mind you, it does look as if a paleoarchaeologist has spread out the bones of an Australopithecus to see what he’s dug up.

There was almost no possibility of restoring the majority of the radiator. The cores were battered and brittle, the lower tank had been abused with various 'attempts' at repair, and the top was detached and twisted. It was decided that only the dome and two sides could be retained, and the remainder would have to be built from scratch.

Tinplate cores were threaded onto 1/4" copper tubes, 70 to each tube. They were dipped in liquid flux, then dipped into molten solder in a propane-heated trough. The top and bottom tanks were made of 18g sheet brass.

Radiator Trough

Dipping Setup

Cores

Header

Radiator

The body is made from poplar (American white wood) as per original specification. The Morgan Three Wheeler Club supplied drawings for these parts taken from original examples. Cardboard templates were formed over the wooden body (as seen on the scuttle in the centre picture) and their dimensions transferred to the sheet metal.

Woodwork

Sheet metal

Bonnet

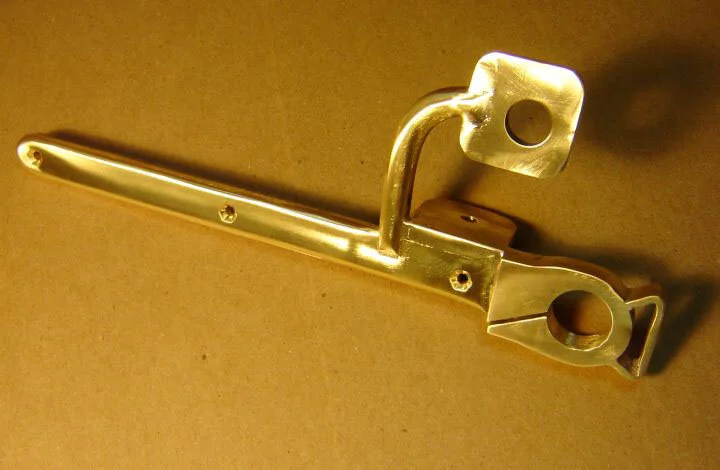

A large number of small parts had to be made including engine plates (the existing ones were defective), windscreen brackets, oil and petrol tanks, steering wheel, battery box and upholstery. Here’s a gallery showing just a few of the many bits:

Tanks

Seat

Steering Wheel

Battery Box

Engine Plates

Bracket

Finally, the Grand Prix was disassembled, brought up from the basement workshop and reassembled. It is seen here in its primer, before hand-painting and finishing work. The 1929 Aero and the trailer share this picture.

We owe a great debt of gratitude to all who helped us with information during the restoration. In particular, Stephen Clark who was free with details and dimensions of his very original Grand Prix.